Yves here. I know this idea may seem sound on some level, but I suspect most people would rather eat bugs than eat food made from bacteria that ate up plastic If nothing else, it has taken decades to work out that ultra processed foods like high fructose corn syrup are bad for you. Any bacteria-derived food intuitively seems so removed from what humans have evolved to consume, particularly in terms of diversity and almost certain lack of micro-nutrients, that it’s hard to see it as a good idea. And one can therefore further imagine that the affluent and the health conscious will reject this as “food”.

But the odds seem high that any “bacteria that ate plastics” calorie source will be fed to animals instead….which will lead to further bifurcation, of “grass fed”, “free range” or other non-Frankenfood fattened animal (or dairy) product for those that can afford it, and yet another variety of factory food for everyone else. The story effectively acknowledges this; the envisaged use is on a very short-term, emergency basis.

The article also mentions using reactors and “high heat” to process the plastics. What is the energy cost?

By Sara Talpos, a contributing editor at Undark. Originally published at Undark

In 2019, an agency within the U.S. Department of Defense released a call for research projects to help the military deal with the copious amount of plastic waste generated when troops are sent to work in remote locations or disaster zones. The agency wanted a system that could convert food wrappers and water bottles, among other things, into usable products, such as fuel and rations. The system needed to be small enough to fit in a Humvee and capable of running on little energy. It also needed to harness the power of plastic-eating microbes.

“When we started this project four years ago, the ideas were there. And in theory, it made sense,” said Stephen Techtmann, a microbiologist at Michigan Technological University, who leads one of the three research groups receiving funding. Nevertheless, he said, in the beginning, the effort “felt a lot more science-fiction than really something that would work.”

That uncertainty was key. The Defense Advanced Research Projects Agency, or DARPA, supports high-risk, high-reward projects. This means there’s a good chance that any individual effort will end in failure. But when a project does succeed, it has the potential to be a true scientific breakthrough. “Our goal is to go from disbelief, like, ‘You’re kidding me. You want to do what?’ to ‘You know, that might be actually feasible,’” said Leonard Tender, a program manager at DARPA who is overseeing the plastic waste projects.

The problems with plastic production and disposal are well known. According to the United Nations Environment Program, the world creates about 440 million tons of plastic waste per year. Much of it ends up in landfills or in the ocean, where microplastics, plastic pellets, and plastic bags pose a threat to wildlife. Many governments and experts agree that solving the problem will require reducing production, and some countries and U.S. states have additionally introduced policies to encourage recycling.

For years, scientists have also been experimenting with various species of plastic-eating bacteria. But DARPA is taking a slightly different approach in seeking a compact and mobile solution that uses plastic to create something else entirely: food for humans.

The goal, Techtmann hastens to add, is not to feed people plastic. Rather, the hope is that the plastic-devouring microbes in his system will themselves prove fit for human consumption. While Techtmann believes most of the project will be ready in a year or two, it’s this food step that could take longer. His team is currently doing toxicity testing, and then they will submit their results to the Food and Drug Administration for review. Even if all that goes smoothly, an additional challenge awaits. There’s an ick factor, said Techtmann, “that I think would have to be overcome.”

The military isn’t the only entity working to turn microbes into nutrition. From Korea to Finland, a small number of researchers, as well as some companies, are exploring whether microorganisms might one day help feed the world’s growing population.

According to Tender, DARPA’s call for proposals was aimed at solving two problems at once. First, the agency hoped to reduce what he called supply-chain vulnerability: During war, the military needs to transport supplies to troops in remote locations, which creates a safety risk for people in the vehicle. Additionally, the agency wanted to stop using hazardous burn pits as a means of dealing with plastic waste. “Getting those waste products off of those sites responsibly is a huge lift,” Tender said.

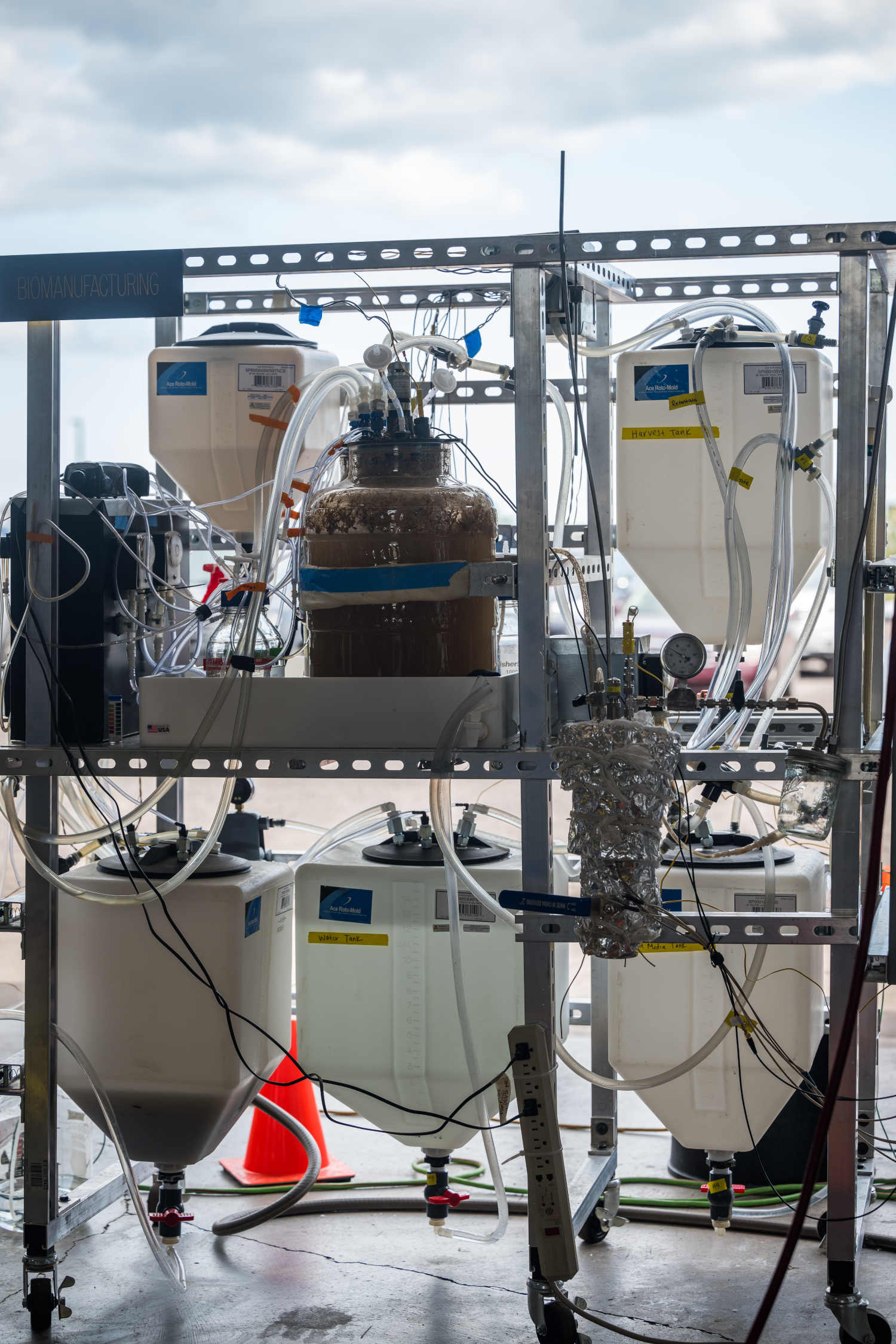

The Michigan Tech system begins with a mechanical shredder, which reduces the plastic to small shards that then move into a reactor, where they soak in ammonium hydroxide under high heat. Some plastics, such as PET, which is commonly used to make disposable water bottles, break down at this point. Other plastics used in military food packaging — namely polyethylene and polypropylene — are passed along to another reactor, where they are subject to much higher heat and an absence of oxygen.

Under these conditions, the polyethylene and polypropylene are converted into compounds that can be upcycled into fuels and lubricants. David Shonnard, a chemical engineer at Michigan Tech who oversaw this component of the project, has developed a startup company called Resurgent Innovation to commercialize some of the technology. (Other members of the research team, said Shonnard, are pursuing additional patents related to other parts of the system.)

In one reactor, shown here at a recent MTU demonstration, some deconstructed plastics are subject to high heat and the absence of oxygen — a process called pyrolysis. Visual: Kaden Staley/Michigan Technological University

After the PET has broken down in the ammonium hydroxide, the liquid is moved to another reactor, where it is consumed by a colony of microbes. Techtmann initially thought he would need to go to a highly contaminated environment to find bacteria capable of breaking down the deconstructed plastic. But as it turned out, bacteria from compost piles worked really well. This may be because the deconstructed plastic that enters the reactor has a similar molecular structure to some plant material compounds, he said. So the bacteria that would otherwise eat plants can perhaps instead draw their energy from the plastic.

After the bacteria consume the plastic, the microbes are then dried into a powder that smells a bit like nutritional yeast and has a balance of fats, carbohydrates, and proteins, said Techtmann.

Materials for the MTU project are shown at a recent demonstration. Before being placed in a reactor, plastic feedstocks (bottom row) are mechanically shredded into small pieces. Visual: Kaden Staley/Michigan Technological University

After PET is broken down in the ammonium hydroxide, the liquid is moved to a reactor where it is consumed by a colony of microbes. Visual: Kaden Staley/Michigan Technological University

Research into edible microorganisms dates back at least 60 years, but the body of evidence is decidedly small. (One review estimated that since 1961, an average of seven papers have been published per year.) Still, researchers in the field say there are good reasons for countries to consider microbes as a food source. Among other things, they are rich in protein, wrote Sang Yup Lee, a bioengineer and senior vice president for research at Korea Advanced Institute of Science and Technology, in an email to Undark. Lee and others have noted that growing microbes requires less land and water than conventional agriculture. Therefore, they might prove to be a more sustainable source of nutrition, particularly as the human population grows.

Lee reviewed a paper describing the microbial portion of the Michigan Tech project, and said that the group’s plans are feasible. But he pointed out a significant challenge: At the moment, only certain microorganisms are considered safe to eat, namely “those we have been eating thorough fermented food and beverages, such as lactic acid bacteria, bacillus, some yeasts.” But these don’t degrade plastics.

Before using the plastic-eating microbes as food for humans, the research team will submit evidence to regulators indicating that the substance is safe. Joshua Pearce, an electrical engineer at Western University in Ontario, Canada, performed the initial toxicology screening, breaking the microbes down into smaller pieces, which they compared against known toxins.

“We’re pretty sure there’s nothing bad in there,” said Pearce. He added that the microbes have also been fed to C. elegans roundworms without apparent ill-effects, and the team is currently looking at how rats do when they consume the microbes over the longer term. If the rats do well, then the next step would be to submit data to the Food and Drug Administration for review.

At least a handful of companies are in various stages of commercializing new varieties of edible microbes. A Finnish startup, Solar Foods, for example, has taken a bacterium found in nature and created a powdery product with a mustard brown hue that has been approved for use in Singapore. In an email to Undark, chief experience officer Laura Sinisalo said that the company has applied for approval in the E.U. and the U.K., as well as in the U.S., where it hopes to enter the market by the end of this year.

Even if the plastic-eating microbes turn out to be safe for human consumption, Techtmann said, the public might still balk at the prospect of eating something nourished on plastic waste. For this reason, he said, this particular group of microbes might prove most useful on remote military bases or during disaster relief, where it could be consumed short-term, to help people survive.

“I think there’s a bit less of a concern about the ick factor,” said Techtmann, “if it’s really just, ‘This is going to keep me alive for another day or two.’”